SAFETY HEALTH ENVIRONMENT QUALITY POLICY

Zuva Petroleum is an organisation that is involved in the procurement, handling, storage and distribution of petrochemical products. Management and staff are committed to focusing on customer requirements through innovation, technological advancement and delivering an excellent service in a safe environment. We recognise the risks and hazards caused by our activities, products and services and we are committed to eliminating or mitigating these hazards through implementation of an Integrated Management System based on ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018.

The Integrated Management System is Strategic to our Business, hence our commitment to going beyond compliance by;

1.1. Providing a Safe and Healthy working environment for the prevention of Work related injuries and Ill-health.

1.2. Motivating our workforce to professional, ethical, loyal, and honest conduct.

1.3. Fostering ZERO tolerance to unsafe acts and conditions and participating in the Global Vision Zero Initiative and taking additional measures considered necessary.

1.4. Complying with and raising awareness of all applicable local and international compliance obligations, including voluntary requirements.

1.5. Being responsible for our Contractor SHEQ Management systems and performance.

1.6. Being a leader in Sustainability, fostering a positive. culture for our employees and surrounding community.

1.7. Improving our SHEQ Management and performance through the engagement of all employees and stakeholders.

1.8. Making line supervision responsible for setting objectives, achieving results through active participation and consultation of employees to ensure the effective implementation of the management systems.

1.9. Making Line supervision responsible for SHEQ results and for the active participation of their departmental employees

1.10. Conducting assurance activities at all levels of the organization to evaluate work practices and the effectiveness of SHEQ programs.

1.11. Ensuring customer satisfaction by offering products and services that meet local and international standards.

1.12. Ensuring customer satisfaction by supplying products and services that meet international standards.

1.13. Communicating the policy to all interested parties, reviewing it regularly and taking necessary steps to continually improve the systems.

PERSONAL PROTECTIVE EQUIPMENT AND CLOTHING (PPE/C)

2. POLICY STATEMENTS

2.1. Zuva Petroleum considers its employees, contractors and visitors to be of paramount importance and undertakes to safeguard them through providing and maintaining, as far as reasonably practical, a working environment that is safe and without risk to the health of its employees, contractors and visitors.

2.2. In ensuring a safe and healthy working environment all employees and contractors of Zuva Petroleum shall work closely together with the employer in minimizing any risk that might jeopardize their health and safety

2.3. Personal protective equipment is not a replacement for good engineering controls, administrative controls or work practices. Rather, PPE/C should be used in conjunction with these controls to ensure the health and safety of employees, visitors and contractors.

2.4. PPE/C is regarded as a ‘last line of defence’ in terms of protecting against risks to health and safety. Although a risk assessment may identify PPE/C as being necessary, other means of control shall be given preference, and wherever possible, PPE/C must not be relied upon as the sole means of protection.

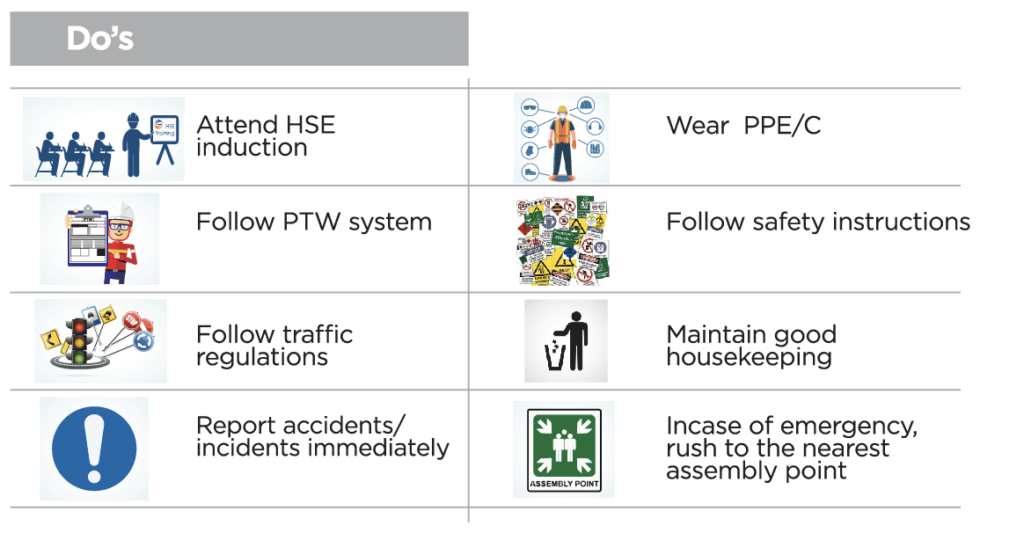

2.5. Zuva expects all employees, visitors and contractors to put on relevant PPE/C at designated areas at all times.

NB. PPE/C is to be stored as per the manufacturers standards.

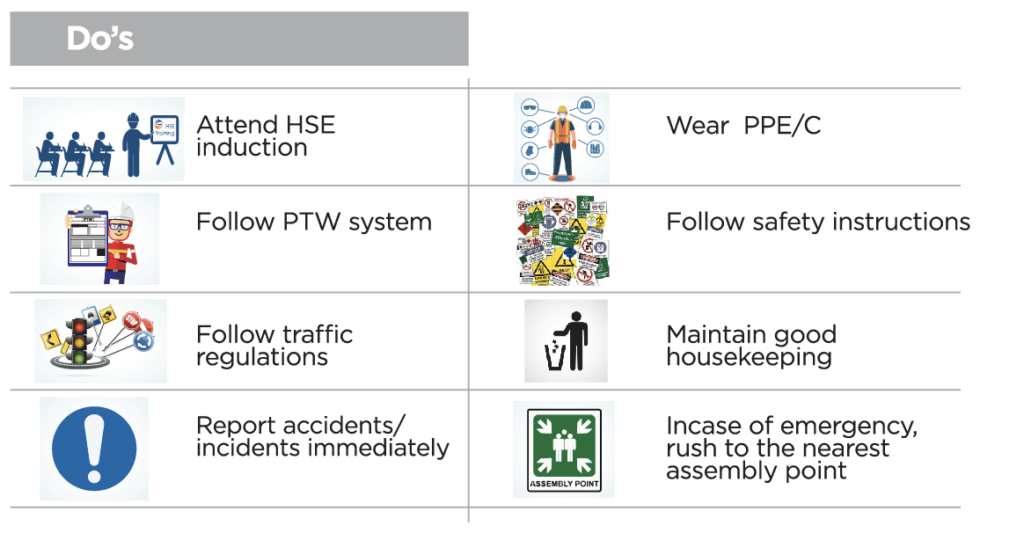

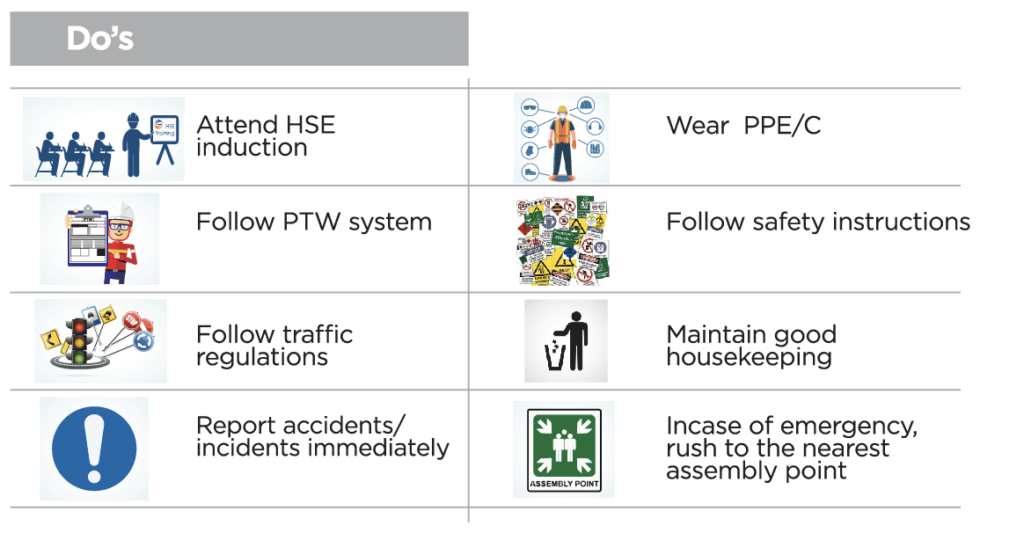

3. Zuva Golden Rules

The aim of the Golden Rules is to prevent severe injuries and fatalities, and to support the journey towards a Leading SHEQ performance and culture.

3.1. Permit to Work

We will use the Permit to Work system where necessary to ensure hazards and risks are understood and controlled.

3.2. Energy Isolation

We will use LOTO (Lock-Out Tag-Out) to verity energy isolation when servicing or maintaining equipment.

3.3. Ground disturbance

We will conduct a risk assessment before any man-made ground disturbance is commenced.

3.4. Confined Space Entry

We will use a permit to work to ensure that confined spaces are safe to enter and that all safety precautions are in place.

3.5. Working at Heights

We will only work at heights when the required safety measures to prevent falls are in place.

3.6. Lifting Operations

We will ensure lifting operations utilizing cranes or other lifting devices are carried out safely.

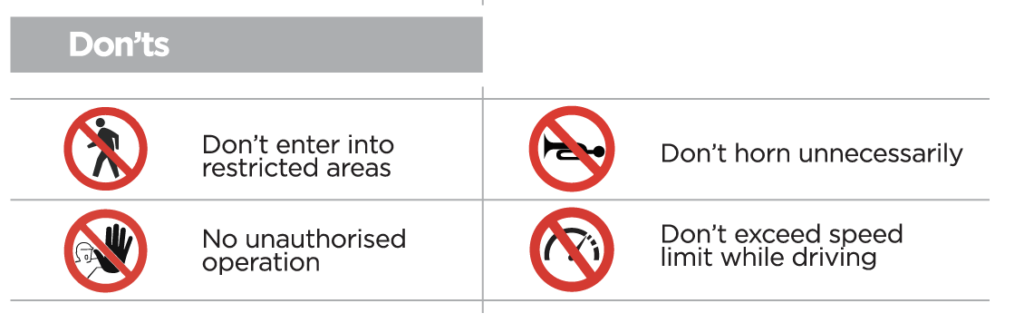

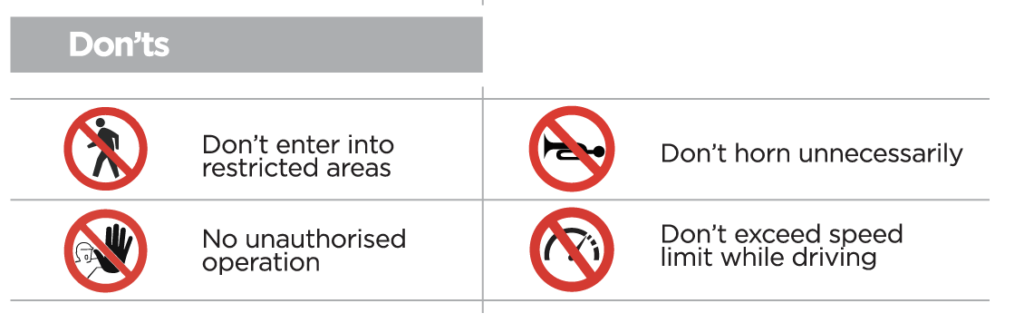

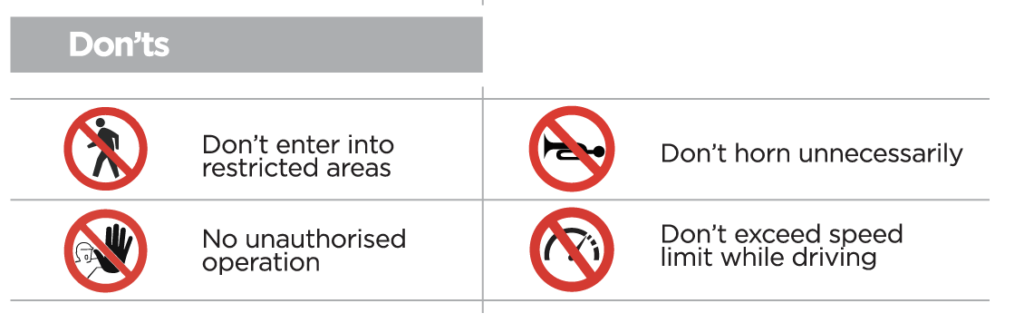

3.7. Driving Safety

We will always operate our vehicles safely and responsibly and use the safety equipment provided.

3.8. Management of Change (MOC)

We will only proceed with technical changes to process plants and process equipment when an Engineering Management of Change process addressing the safety risks has been completed.

EMERGENCY INSTRUCTIONS

EMERGENCY INSTRUCTIONS

In the event of an emergency, a continuous siren is sounded. On hearing the

sound of the siren, evacuate the premises immediately.

DURING AN EMERGENCY

• Immediately stop whatever you are doing.

• Do not delay by picking up belongings.

• Do not run but walk briskly.

DURING AN EVACUATION

• Follow the escape routes marked by the directional arrows and you will be guided to the emergency exits.

• Proceed to the emergency assembly point provided.

• A roll call is conducted

• Await further instructions from the emergency team leader.